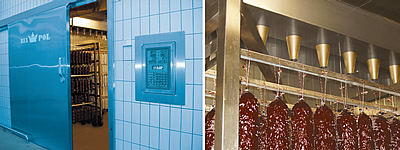

Curing and maturing chambers

Curing and maturing chamber has been designed for thermal processing of meat and cured meat products. Thanks to the use of fully programmable controlling unit every known curing and maturing processes of cured meat products can be realized in our chamber.

Basic task of controlling unit is smooth regulation of the parameters of maturing process (temperature, relative humidity and process time). If a curing and maturing chamber is equipped with smoke generator, a controlling unit will start it at a defined moment of production process.

Fully automated construction of the curing and maturing chamber ensures uniform circulation of cured air within the volume of material placed inside a chamber. Constant quality of the products is also ensured by proper distribution of the products inside device, especially on the trolleys.

Curing and maturing chamber is intended for processes of ripening, drying, hot and cold smoking and storing of cured meat products, hams, bacons etc. The chamber is designed for production of raw-ripening cured meat products, salami and other long-life products (fish, poultry and cheese).

Process of maturing is realized within the range of temperatures from 12° C to 30° C and relative humidity of air between 60% and 95%. Depending on the type of product, at full load of the standard trolleys the maximum weight loss in 24 hours does not exceed 4%.

Existing rooms can be also adapted for curing and maturing chamber - a “tailor-made” chamber.

A system of air channels is made only from acid resistant steel. There are two intake channels (left and right) and depending on the room’s width a system of exhaust channels consists of two or more aspirating channels. Uniform distribution of the cured air is ensured by adjustable air flaps situated in the intake channel. Establishing the size of air “trombones” mounted in the intake channels is made according to the size of the chamber or volume of the circulating air. Depending on the size of processing zone with application of the proper air flaps combination an alternating air feeding is used to ensure proper air circulation within the volume of curing and maturing chamber.

Universal microprocessor controller of curing and maturing chamber allows for realization of every process used in technology of cured meat products maturing with full visualization on the touch-panel display.

High safety of the processes in the chamber is ensured by:

- efficient and economic air flow system,

- automation of work with given humidity and temperature,

- growth control of undesired mould and dye penetration,

- control of water activity on the surface or products,

- microclimate allowing for obtaining clean and dry surface on a product what has an influence on the general appearance, structure and consistence of the products.

Technical data

The table below presents example parameters of curing and maturing chambers.