Oferujemy usługi z zakresu cięcia laserowego. Dysponujemy nowoczesnym sprzętem ... |

Koncepcja firmy Rex-Pol to bezwzględny nacisk na jakość produkowanych urządzeń, bezpieczeństwo i kompetencję ... |

© Rex-Pol Sp. z o.o.

41-508 Chorzów ul. Wiejska 18 tel./fax (0048 32) 245 90 34 e-mail: rexpol@rexpol.pl |

Produkty

|

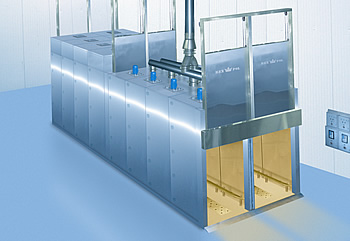

Blast cooling chambers

Blast cooling chambers are intended to cool the products directly after thermal processing. Process of rapid taking heat away prevents the growth of bacteria and rapid water evaporation. Thanks to that the products retain color, taste, aroma and proper moisture. Fully automated blast cooling process ensures:

Blast cooling chambers are equipped with high-class microprocessor controller ensures automated regulation of parameters of cooling process. Additionally, proper air circulation in the chamber ensures uniform cooling in the whole volume of the chamber. Microprocessor controller in the blast cooling chamber allows for saving the cooling process parameters and the process data saving precisely meats HACCP standards. Blast cooling chambers are manufactured in standard and passage, one and several-trolley versions equipped with coolers:

|